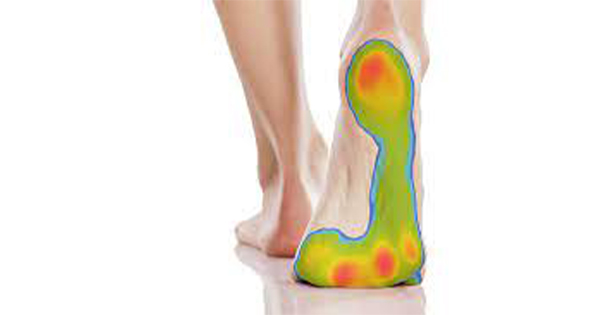

In the diabetic foot, plantar pressure measurement is used for the following reasons:

- To screen and assess patients

- To quantify the efficacy of interventions such as dressings, insoles, orthoses, footwear, casting, and surgery

- As a health education tool.

The authors remain committed to evaluating systems against the ‘ideal’ criteria outlined in the International Protocol Guidelines for Plantar Pressure Measurement (Barnett, 1998) and are unable to ‘recommend’ specific systems.

General considerations

First, it is important to state that there is no one perfect plantar pressure measurement system – all systems have advantages and disadvantages. It is important to choose the system best able to meet the individual requirements of each user. It is vital to have a clear idea of the information that you want the system to give you, a profile of the patients that you wish to examine, and details of the location(s) in which the system will be used. With these parameters in mind, a variety of issues should then be examined. Plantar pressure measurement systems divide broadly into two categories:

- Platform

- In-shoe.

The user needs to decide which option will best fit his/her requirements.

Platform versus in-shoe

Platforms enable collection of data in a barefoot state, removing the influence of footwear, which can mask high pressures. The entire foot/ground contact is captured, providing the subject manages to hit the data acquisition area; and the subject has no wires or data boxes attached to them, which could influence their gait. Some platform systems require insertion into a walkway to accommodate their depth, otherwise the subject has to step up and step down during data acquisition – this would add an additional variable to the gait. However, many platforms are slim enough to simply be placed on the floor. Ideally, the data sampling area of the platform should be as large as possible, to enable the subject to easily ‘hit’ the platform without needing to target. A large sampling area is also helpful if the platform is to be camouflaged to prevent targeting, enabling successful data acquisition in less walks. If the platform is to be covered in this way, it is important to liaise with the manufacturers as the covering may affect data acquired.

All platform systems require a firm, homologous surface to function on, with sufficient space for the subject to take several steps before and after data acquisition. If a portable system is required, it is important that such a surface and area will be available at all sites of use; and the platform must not be so big that it is hard to transport without damage to the platform (or the operator).

In-shoe systems enable collection of data in the foot’s normal functioning environment, and remove the risk of the subject targeting the sensing area. With such systems multiple footsteps from both right and left feet can be collected during a single walk. However, with in-shoe systems there is a risk of the subject’s feet missing part of the sensing area, especially in pre-formed sensor insoles, which come in standard or extra-wide sizes. The subject also has wires and data boxes attached to them, and in some cases they are also attached to the computer. This may adversely affect the normality of their gait.

With in-shoe systems it is important to consider the thickness of the sensor insole itself as it needs to fit into the subject’s shoe. Also, the composition of the insole is important – stiff insoles may elevate pressures and soft sensor insoles may decrease measured pressures. If the sensing insole has a slippery surface subjects may find this affects the normality of their gait. The sensor matrix will have to bend over a curved surface in-shoe. This bending may stress the sensors sufficiently to produce artefact pressure readings, and may also lead to sensors creasing and failing. Therefore, a more flexible, compliant sensor insole is preferable. This, however, will be more prone to hysteresis.

Data acquisition will probably take about the same amount of time regardless of whether the system is a platform or in-shoe, but in-shoe systems will be more fragile, because of the environment that they have to work in and the need for minimal thickness. Some manufacturers produce both types of systems, and have software which can be applied to either, making it possible to have both types of measuring ability with less financial outlay.

Sensors and spatial resolution

Having made the decision to use either platform or in-shoe, it is then important to consider the characteristics of the various systems. Most systems consist of an homologous matrix of sensors, although some in-shoe systems have individual sensors placed at discrete locations. Several different types of electromechanical sensors are used commercially. These include:

- Resistive

- Piezo-electric

- Capacitance sensors.

Urry (1999) provides an excellent review of plantar pressure measurement sensors. In a homologous matrix, with all sensors equally spaced, the number of sensors in one square centimetre equates to the system’s spatial resolution. The larger this number, the more detailed the pressure picture the system produces and, because pressure is derived by dividing force by area, the pressure measured will also be higher (Lord, 1997).

In considering the spatial resolution required one needs to decide the size of the structures being measured, e.g. metatarsal head, heel, lesser toes. With a low spatial resolution there is a risk of missing smaller structures and under estimating pressure. All systems will have ‘dead space’ between the sensors that does not measure pressure. Many systems calculate for this – it is worth checking with the manufacturer and asking how this calculation is achieved.

Sampling frequency

The sampling frequency of the system is very important; this is the frequency with which each individual sensor in the matrix is scanned during data acquisition. (N.B. the frequency with which the entire matrix is scanned is sometimes quoted – this may be very high, but if there are a large number of sensors each one may be scanned very slowly). If the system has a slow sampling frequency, events, which occur very quickly in the gait cycle, may be missed. Systems examining data collected during walking should sample at 50 Hertz (Hz), but for data collected during running 200 Hz is necessary. Impact studies require an even higher sampling frequency.

Dynamic range

The system should also have a dynamic range that will allow it to record both low and high pressures accurately. If the system saturates with high pressures it may miss important changes that are outside the measurement range. In the diabetic foot plantar pressures are often high. An intervention may successfully reduce these pressures, but they may remain outside the system’s dynamic range. The change would therefore not be recorded and quantified, the intervention would be deemed to have failed! In-shoe systems will have a lower dynamic range than platform systems because in-shoe pressures are lower.

Errors

The accuracy, repeatability, and reliability of the various systems are very important. Most systems are calibrated by the manufacturer, and need to be returned to the manufacturer for periodic recalibration. Ideally, the user should be able to recalibrate their system, or at least be able to check the system’s accuracy – the manufacturer should be able to advise on this point.

Some systems have been subjected to independent studies, but a system should not be rejected purely on bench or lab evaluation. Such studies help identify the limitations of systems, and these should be borne in mind when the systems are utilised. Manufacturers often provide guidelines for optimum use of systems and these should be followed. However, the Footpressure Interest Group guidelines (Barnett, 1998) are also useful.

Cost

The cost of the various systems ranges tremendously, but with most systems it is possible to start at a basic level and then upgrade as more funds become available. It is important to consider running costs for the system; usually these are due to sensor replacement. Check with the supplier and users of the system with regard to sensor life expectancy.

Software and support

The software written for the system is also important. Is it clear and easy to use? Most are written for a Windows Microsoft based environment. The software must provide easy access to the data parameters required by the user, with minimal time and effort. These systems generate huge quantities of data that can be daunting to analyse. Ideally, have a very clear idea of the information that you wish to extract, then go through the process of obtaining this information with the supplier. It is helpful if the system can calculate pressure parameters in several units; the user can then utilise the units most familiar to them. However, it is essential that the system should also provide data in SI units, as these should be used in all publications. Investigate the possibility of upgrading the system in the future, and establish whether the supplier will upgrade software free of charge for a period of time after purchase. It is important to speak to other users of the system that you are considering. They are usually happy to discuss pros and cons and will provide information about the standard of after sales support. The Footpressure Interest Group also exists to provide such information, and contact details for many of the manufacturers and suppliers are held on our website (see below).

Please send comments or requests for information to:

Sue Barnett, Room 1E13, S.P.O.T, Faculty of Health and Social Care, University of the West of England, Glenside Campus, Blackberry Hill, Stapleton, Bristol, BS16 1DD.

Tel: 0117 9585655 ext 8507

Fax: 0117 9758408

Email: Sue.Barnett@uwe.ac.uk

Website: http://www.figroup.com